High-Quality Refractory Fiber Board for Superior Heat Resistance

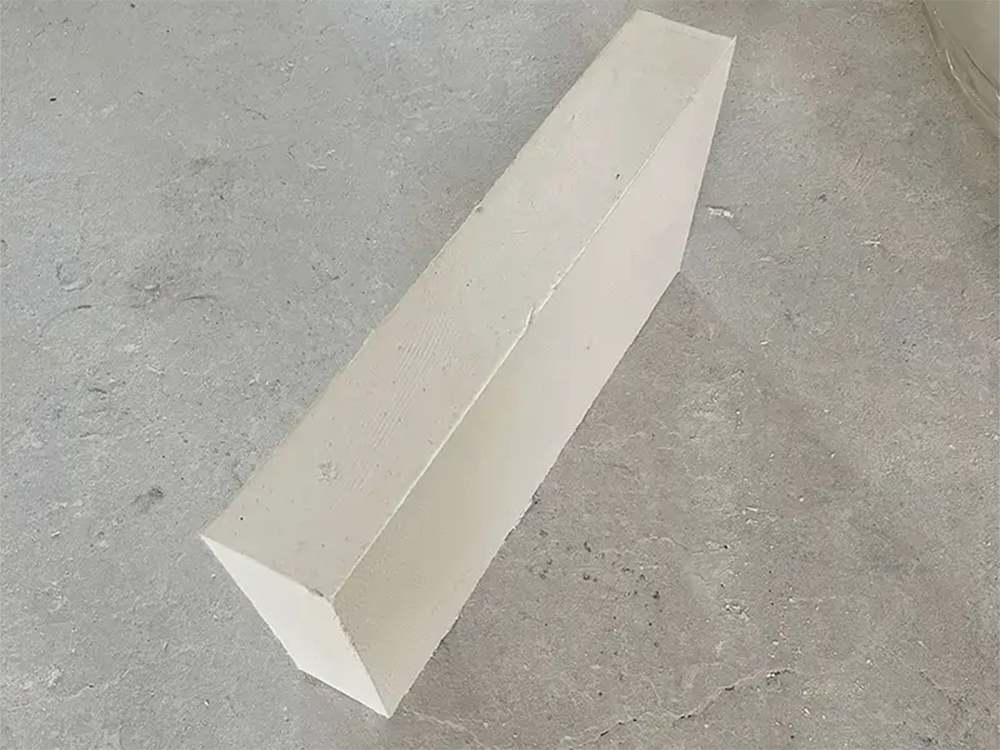

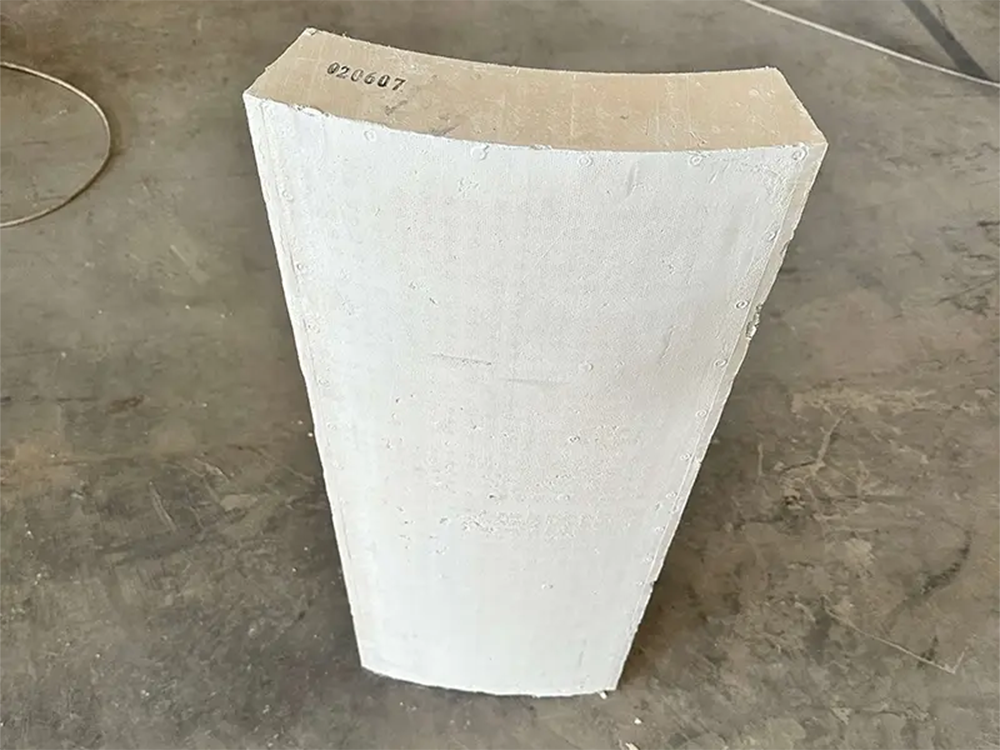

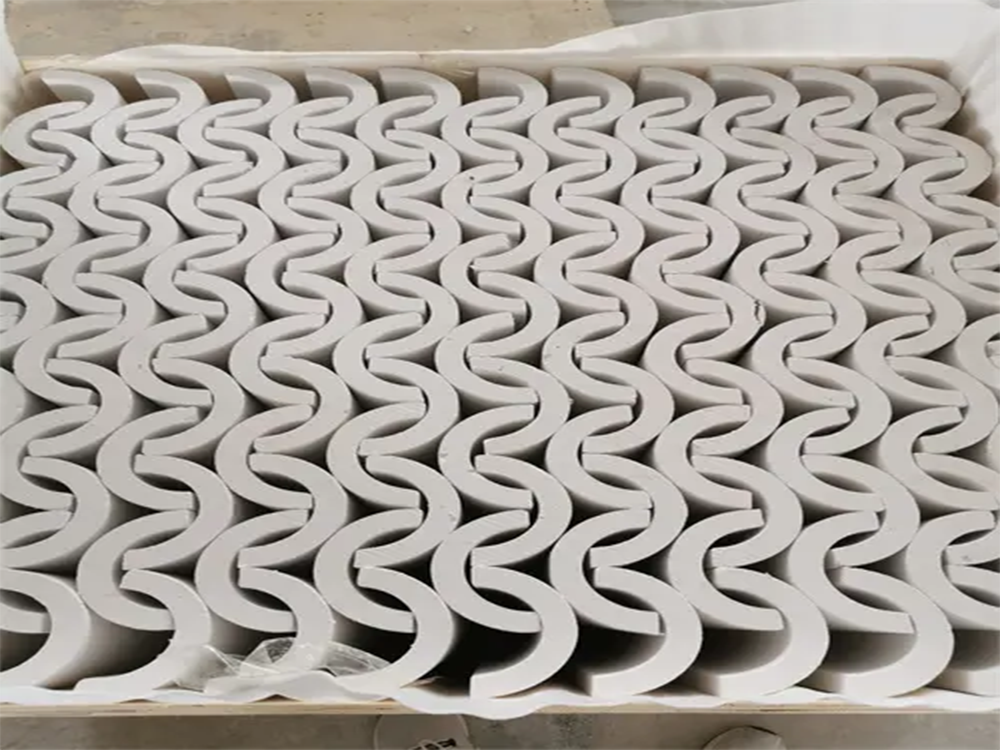

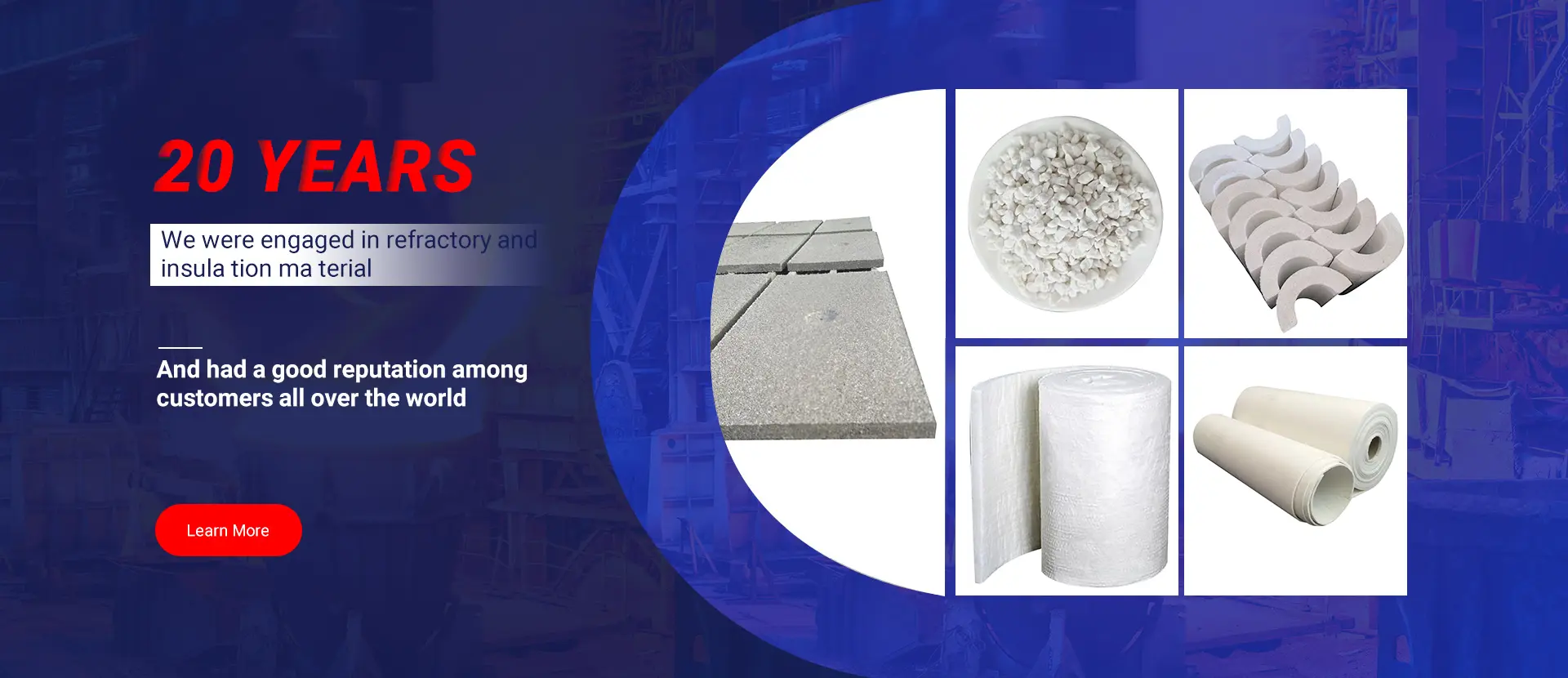

Looking for high-quality refractory fiber board? Look no further than KRS (Shandong) New Material Co., Ltd. Our refractory fiber boards are designed to withstand high temperatures and harsh environments, making them the perfect choice for a wide range of industrial applications, Our refractory fiber board is made from high-quality refractory fibers and binders, ensuring excellent thermal stability and mechanical strength. This makes it an ideal choice for use in furnaces, kilns, and other high-temperature applications. The board is also lightweight and easy to handle, making it convenient for installation and maintenance, At KRS, we are committed to providing our customers with the best products and services. Our refractory fiber board is manufactured to the highest standards, ensuring consistent quality and performance. Whether you need insulation for your industrial furnace or lining for your kiln, our refractory fiber board is the perfect solution, Trust KRS (Shandong) New Material Co., Ltd. for all your refractory fiber board needs. Contact us today to learn more about our products and how they can benefit your business

- Fiberglass Calcium Silicate Board

- Rockwool Acoustic Insulation 100mm

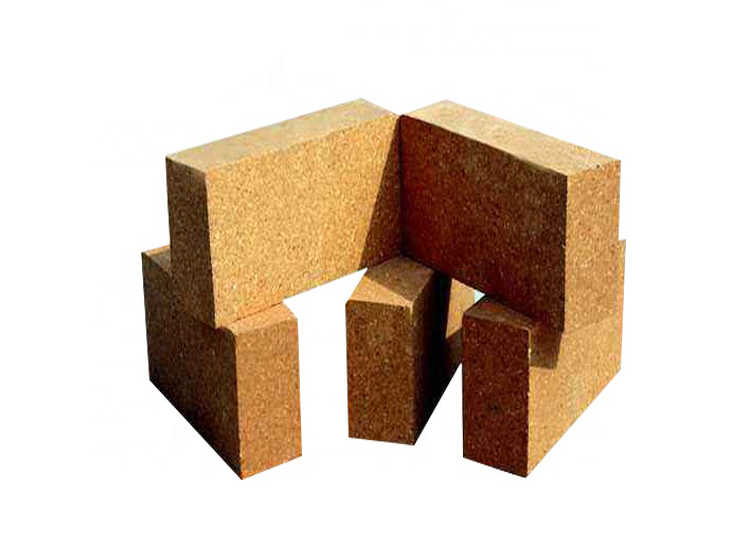

- Insulating Mullite Light Weight Brick

- Insulating Fire Bricks

- Acoustic Rockwool

- Vermiculite Fireproof Door Panel

- Calcium Silicate Plunger Head

- Ceramic Fireproof Blanket

- Thermo 1200 Calcium Silicate Insulation

- Underfloor Heating Insulation Boards 6mm